Reliability – Pumps and their Installation

With pump reliability much is has been written about the pump design and the problems of operating equipment away from the best efficiency point (BEP).

The many standards for pumping equipment give guidance on the levels of acceptable vibration and operational regions where pumps are allowed to run and the appropriate performance criteria they should meet.

The unfortunate situation often occurs though that despite the design and operation of the pump being correct, the reliability of a machine can still be poor.

The reliability of a machine should be viewed as a chain with pump design and operation being only links. Reliability comes from relentlessly perusing the root cause of failure and eliminating the week links from the chain. Once one link is eliminated the next weakest link becomes the focus of attention.

One weak link often ignored within the reliability chain is the pump installation. No matter how well the pump is designed and no matter how precisely the components are manufactured the pump cannot perform reliably if the system it sits within is flawed.

One example of this is way the pump is installed on the baseplate. The pump feet should be fastened hard against the pump mounting pedestals. There should never be any need to install shims under the pump feet.

Large multi-stage pumps generally have 4 feet. If the pump feet or the base plate feet are not constructed correctly it can cause the pump to sit down on 3 feet, as a 3-legged stool would, leaving the 4th foot away from a firm surface and the interface between pump foot and base would be soft.

This situation should be investigated thoroughly as it may indicate a problem with either base plate installation or pump foot machining.

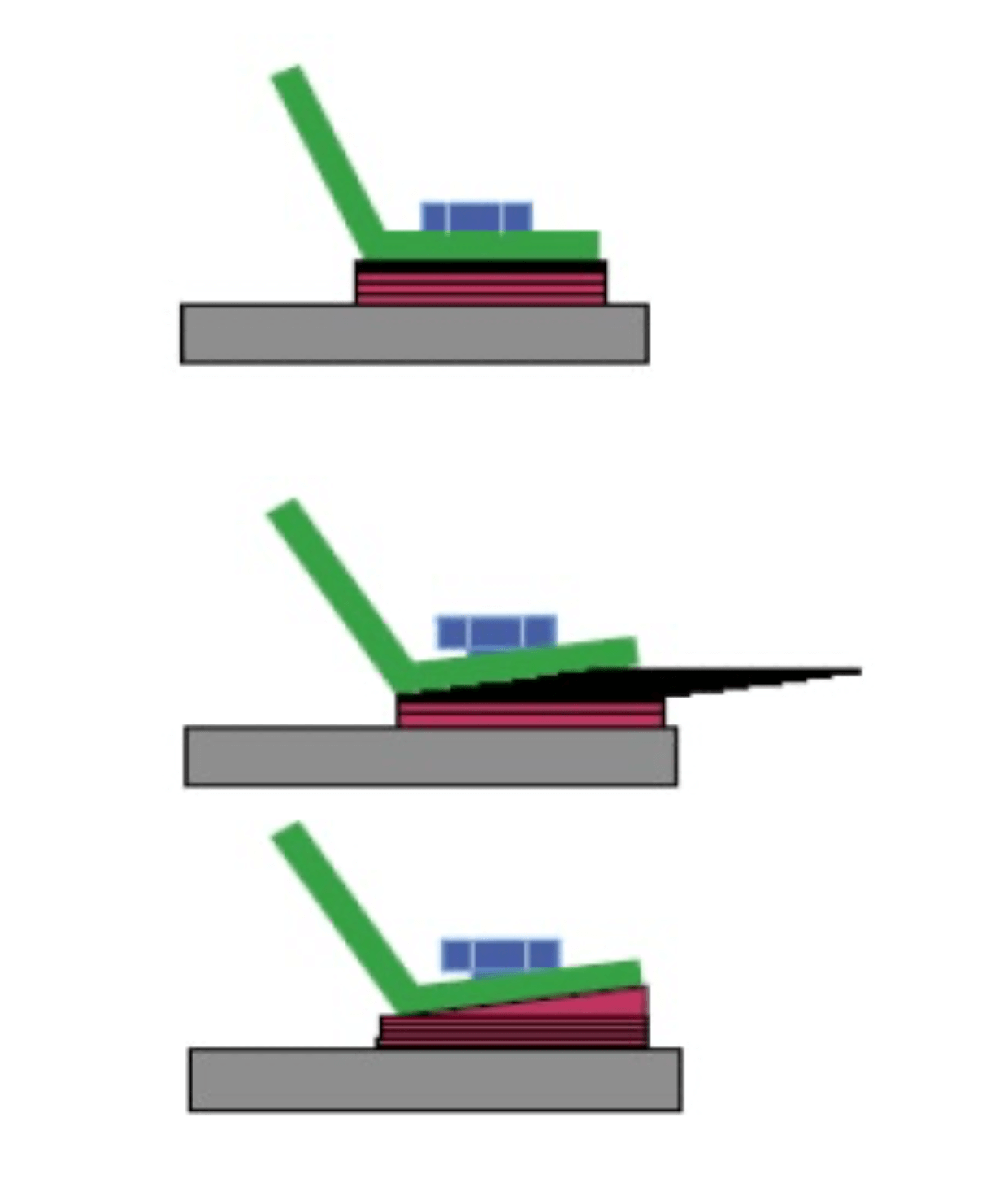

Fig 1 Unsuitable Shim Arrangements

In many cases it is common practice to use unacceptable arrangements to correct soft foot (Fig 1)

Correcting the problem using shims is not ideal but if this is the only available option then the following approach should be adopted:

- Use as one shim as a stack of multiple shims under the pump foot can act as a spring

- Use a shim that covers the full pump foot

It is also important to understand the machine and its operating environment. On a machine in hot service where some amount of thermal expansion is expected such as a BB4 pump in boiler feed service, pump softfoot and shims can be a real problem.

More Recent Articles

-

Pump Efficiency: Half the Story?

It is an insightful practice to view pump efficiency as a combination of 3 factors ...

Mechanical Efficiency: The amount of mechanical power required to turn the rotor and overcome friction ...

More

-

Impeller Vibration

CFD when applied to fluid machines, allows a realistic insight to the internal pressure and ...

Up until quite recently, CFD has chiefly been used for specific problem solving—at least so ...

More