Pump Efficiency: Half the Story?

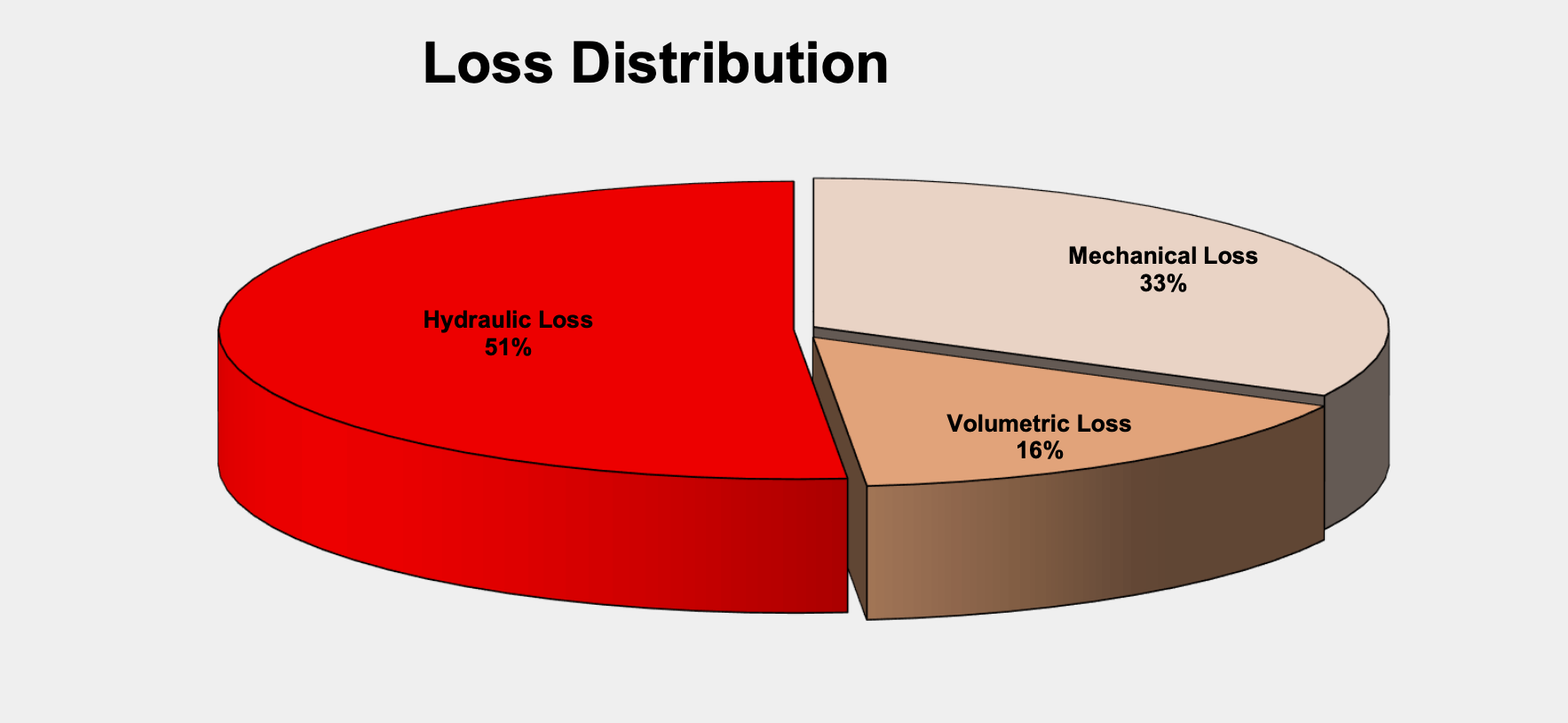

It is an insightful practice to view pump efficiency as a combination of 3 factors coming together to determine the headline efficiency number:

Mechanical Efficiency: The amount of mechanical power required to turn the rotor and overcome friction form bearings, seals, disc friction etc

Hydraulic Efficiency: The designs capability to process the fluid through the passageways of the impeller and casing effetively.

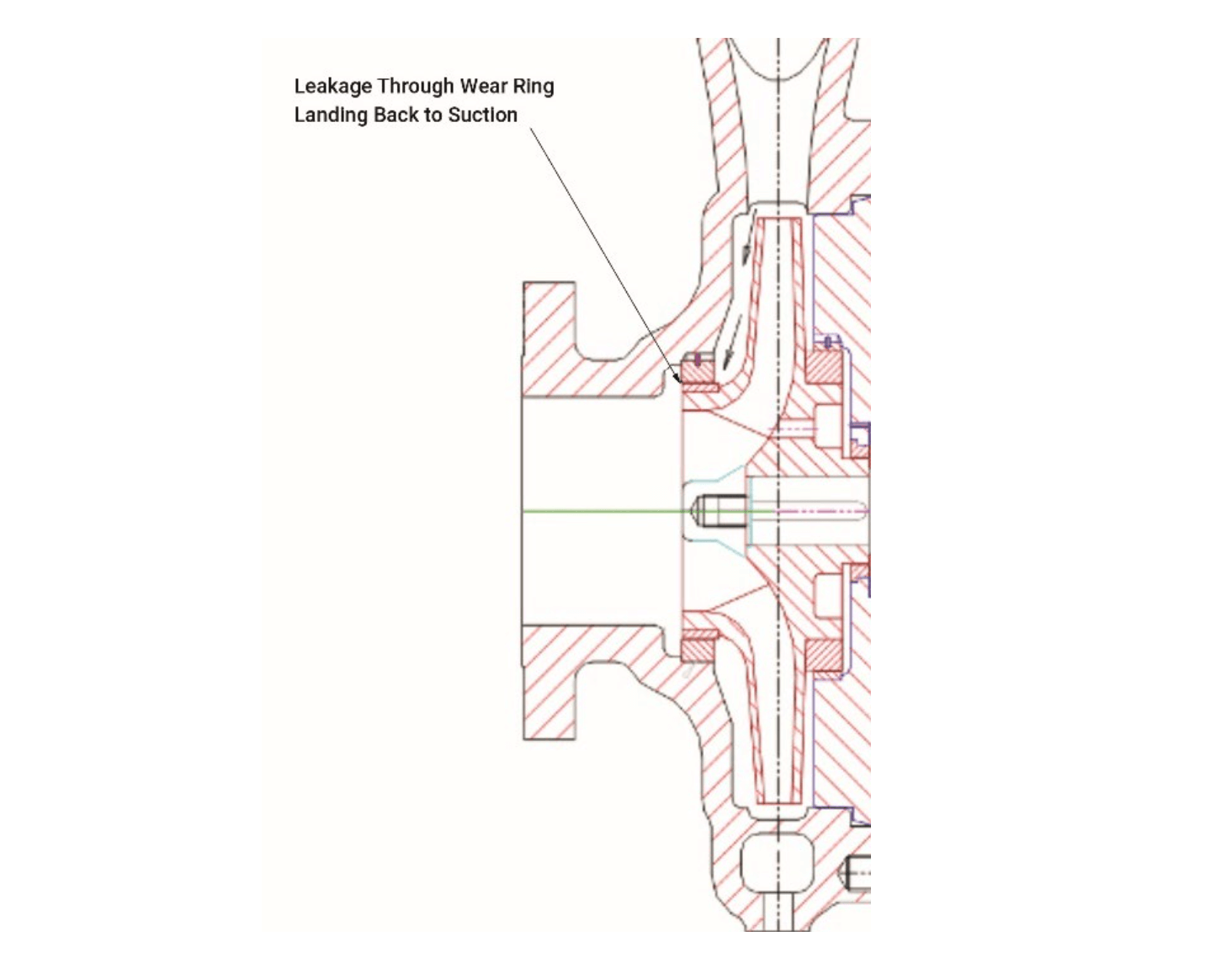

Volumetric efficiency: The designs ability to move all the fluid that enters the suction nozzle out to the discharge nozzle, generally wear ring geometry has a significant on this.

Fig 1 Distribution of Loss that makes up Pump Efficiency

Pumps of different Specific Speeds (Ns) have different characteristics that influence which of these factors is dominant.

A low Ns Pump will be low flow and higher head per stage, this leads to a high differential pressure across the wear ring landing. This driving force across the ring leads to a bigger loss. Superimposed on this is the fact that low NS pumps will have a relatively low flow so as a percentage of total flow the lost flow across the ring will be higher.

The reverse would be true for a high NS pump and the volumetric loss would be a smaller percentage.

Understanding the dominating factors based on the distribution of losses makes it easier to target the correct methodology for improving pump efficiency.

There have been many claims made about the ability of new materials to improve pump efficiency by large amounts by reducing the wear ring clearances by 50%. These claims are generally true but only in specific instances where the dominating factor within the distribution of loss is volumetric.

Fig2 Volumetric Loss over the Wear Ring

When looking at pump curve it is tempting to view the pump efficiency in isolation of the process.

Pump modifications to improve pump efficiency can be valuable but the actual objective is saving consumed power NOT improving pump efficiency.

Improving pump efficiency numbers against the original pump manufacturers curve may be mostly insignificant as the pump is just one element in an interconnected system where piping system, driver efficiency, pump efficiency and process requirements all overlap to provide the real answer. An approach based on overall system efficiency is the way to target the biggest power saving:

Some Considerations of Loss:

Control Valve: Spending money on power to generate head from the pump then throwing away this head across a control valve is a common practice as pumps are often sized for multiple process conditions. Is the pump a match to the process.

Operating Regime: Having a highly efficient pump and running that pump 50% back from best efficiency point where both its efficiency and reliability are considerable less is a consequence of an incorrectly sized machine.

Driver Configuration: Each component of the drive chain has an efficiency number. Every value for motor and gear box must be taken into consideration when assessing the actual power consumption.

Are drive components high efficiency? Some variable speed systems have dramatic reduction in efficiency when the machine is not running at maximum speed.

Process: There may aspects of the process that damage efficiency, abrasive and hot fluids can damage pump efficiency and reliability. Maintenance is expensive and addressing some of the reliability issues may be the correct route to take rather than addressing power consumption.

Conclusion

Pump Efficiency should not be the overriding objective when looking at the cost of ownership. The complex interconnecting variables of pump, driver, process and system provide a greater opportunity for savings. Understanding where to target efforts to generate the largest saving for the least effort/cost is an important consideration.

More Recent Articles

-

Impeller Vibration

CFD when applied to fluid machines, allows a realistic insight to the internal pressure and ...

Up until quite recently, CFD has chiefly been used for specific problem solving—at least so ...

More

-

Mechanical Balance

It is common in centrifugal pumps to balance the rotating components to an internationally recognised ...

Many companies have overarching methodologies that define the procedure as:

Balance individual components, generally on a ...More