Mechanical Balance

It is common in centrifugal pumps to balance the rotating components to an internationally recognised balance standard.

Many companies have overarching methodologies that define the procedure as:

- Balance individual components, generally on a mandrel

- Assemble Components as a rotating element

- Balance rotating element

- Final assemble pump

This overarching procedure should be treated with care. Following this process blindly and expecting the pump to have acceptable balance without great care with the process can lead to a very unexpected result.

Common Problems

Great care must be taken with the components as balance errors can easily creep into the pump even when the spirt of the process is followed but not enough attention to detail and understanding of the machine is applied.

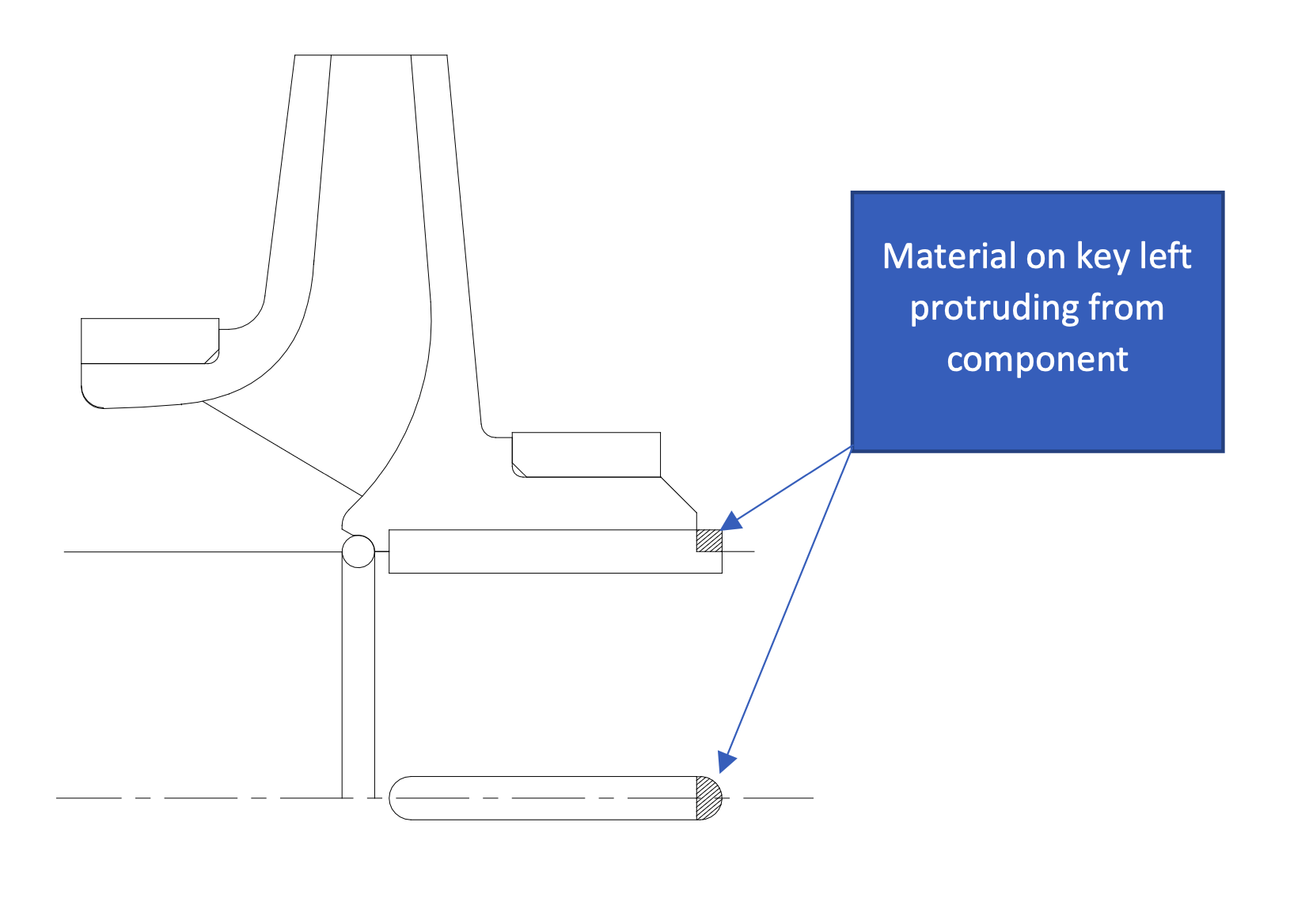

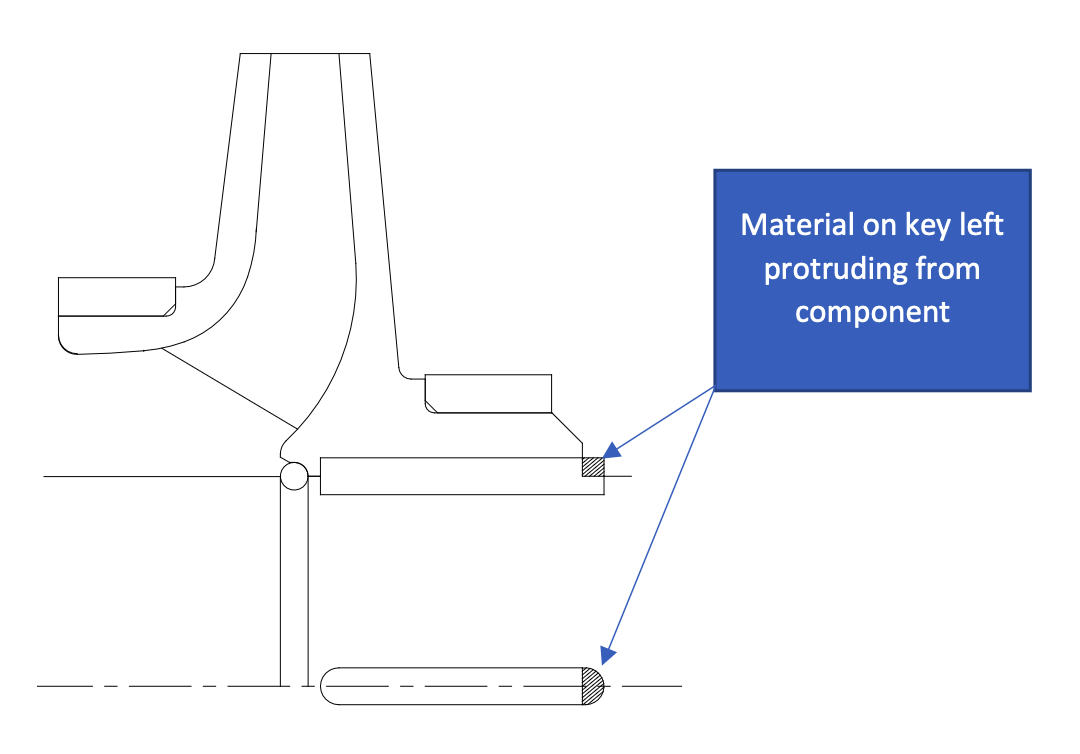

Keys and Keyways

One very common problem is the keyway and its design. Many times, there is an assumption made that the keyway is filled completely by the key. This is rarely the case and on may occasions the key extends out of the back of the component and is not fitted. This can easily be corrected by correct fitting but is a often overlooked, particularly at on the coupling key.

Rotor Design

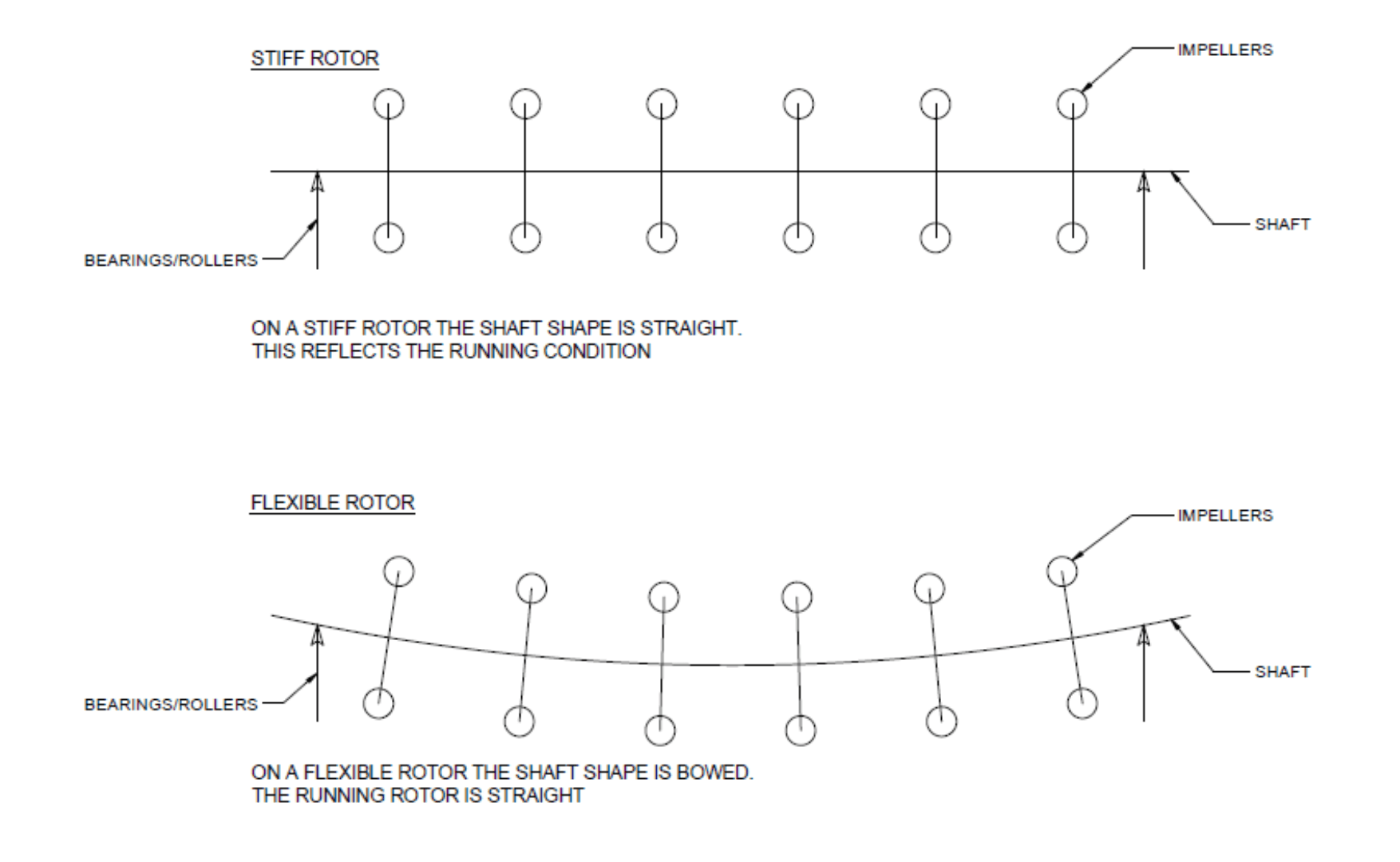

Many rotors are not classically stiff, the pump runs above the first critical speed. On a stiff rotor pump when it is placed on the hard rollers of a balance machine there is little sag in the assemble rotating element. The running position of this rotating element when installed within the pump will correlate strongly with the running position on the balance machine. Corrections to the balance on based on the balance machine will manifest as improvements in balance when the pump is in operation.

On a flexible rotor the result may be very different. In operation the force of the pressure differential across the wear rings is dominant and is enough to pull the rotor straight in operation.

That means that the running position of a flexible rotor pump on a balance machine vs the running position of a flexible rotor pump in actual operation is very different.

Modifications to the rotor balance based on the readings on the balance machine will not necessarily lead to an equivalent improvement in mechanical balance.

On top of this many pump configurations require the element to be disassembled after the balance process to allow stationary wear parts and/or diffuser assemblies to be added. This disassembly destroys the balance unless it can be assured that the components can be replaced in the same exact position on reassembly.

Machining

Manufacturing has a great influence on balance.

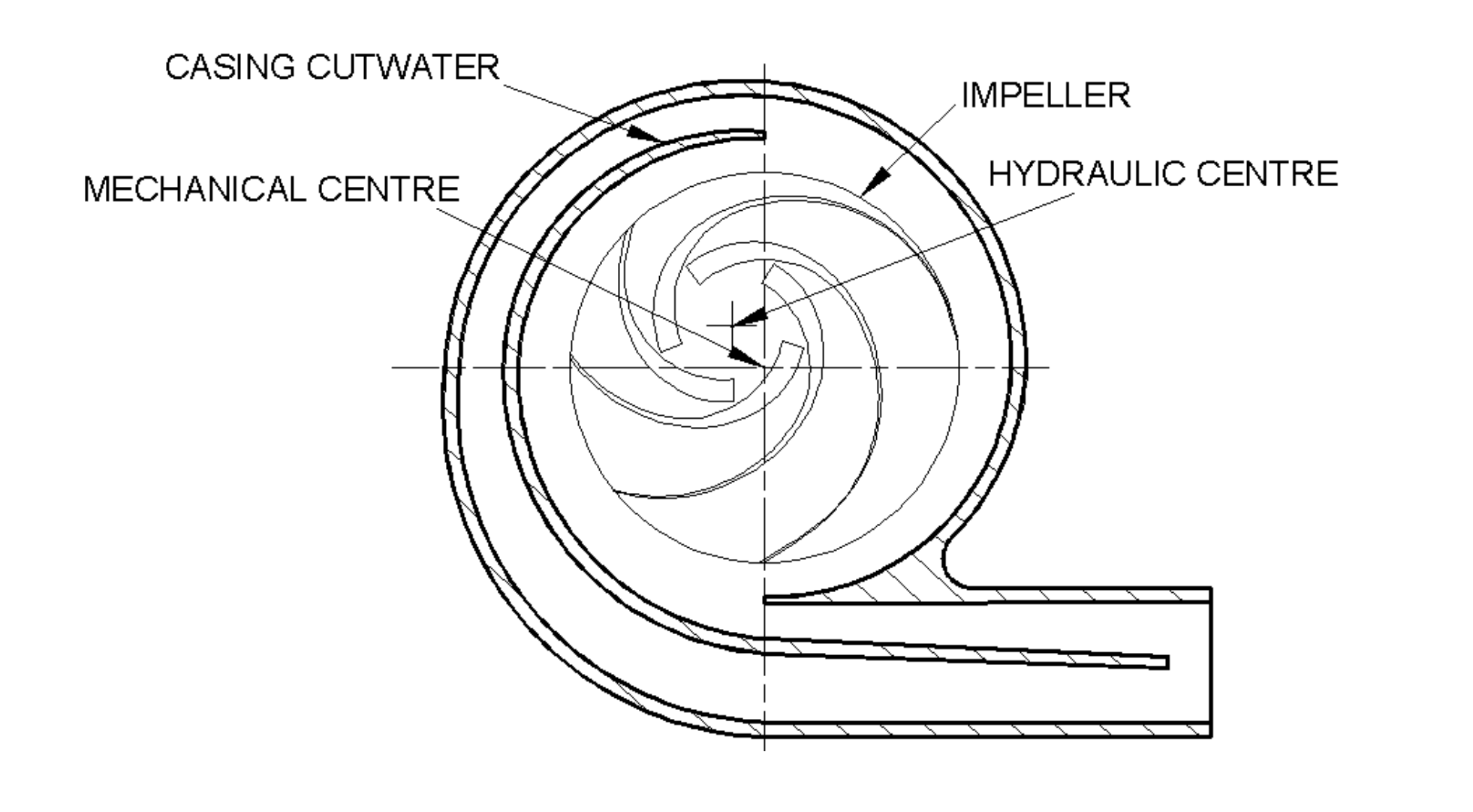

If the Hydraulic centre of the impeller does not exactly align with the mechanical centre of the component there will always be an out of balance component of vibration irrespective that the mechanical balance in air is perfect.

Attention to detail and understanding are the keys to achieving a minimised out of balance component. Blind application without considering the machine design is not a successful strategy.

More Recent Articles

-

Pump Efficiency: Half the Story?

It is an insightful practice to view pump efficiency as a combination of 3 factors ...

Mechanical Efficiency: The amount of mechanical power required to turn the rotor and overcome friction ...

More

-

Impeller Vibration

CFD when applied to fluid machines, allows a realistic insight to the internal pressure and ...

Up until quite recently, CFD has chiefly been used for specific problem solving—at least so ...

More