Environmental regulations are now driving many customers to change and modify their pump equipment to satisfy emission standards. This need generated a request for a replacement pumps with full compliance to the latest European Directives. Following the requirements of API 610 (latest edition) whilst incorporating modern design features.

PumpXP were contracted to review a Raffinate Pump with a view to replacing the old unit with a modern BB3 design.

Existing Pump Review

The existing pump installation was a horizontal BB4 type pump in single operation with an installed spare. The pump was NOT designed in accordance with the requirements of any industry recognised standards.

Duty did not match the customers new requirements. The customer required 3% more flow and 17% more head at duty conditions.

The pump only had single mechanical seals installed.

Proposal

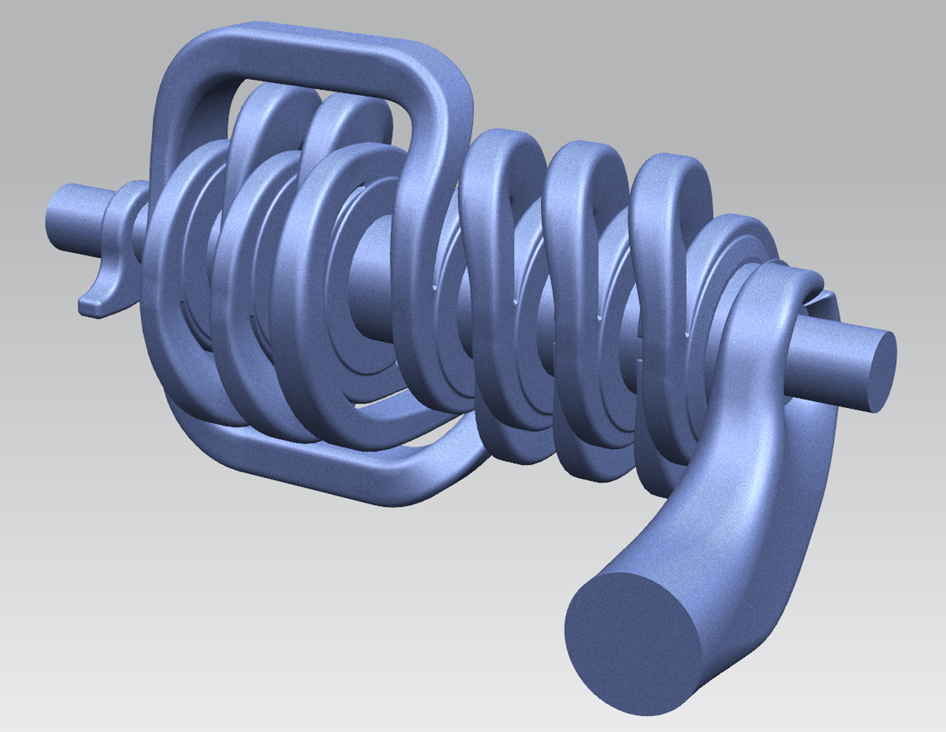

We replaced the pump with a specially designed 9 stage horizontal axially split BB3 pump to meet the new duty.

This pump included all the latest industry design features in full compliance with the latest edition of API 610 standard. With the axial split design meeting the pressure containment requirements of API 610 that would not be provided by the original ring section pump.

PumpXP included double mechanical seals with API seal support systems to facilitate product containment.

The pump was to be supplied fully CE marked in accordance with EU legislation, with ATEX certification as required.

Execution

PumpXP took responsibility for the complete pump design and supply chain of major components working closely with the foundry to ensure product quality.

PumpXP offered support throughout the manufacturing and machining process of the case and had engineers on site to ensure the element build, balance, final pump build and pump testing went to plan.

PumpXP also conducted the risk assessment for the pump and instructions for compilation of the technical manual for full CE and ATEX compliance.

The pump was successfully built and tested and supplied for installation at site.

PumpXP are the only independent company who will design bespoke machines. We can offer bespoke machines to fit in existing spaces ensuring minimum disruption to pipework etc.

In many instances the cost of disruption to piping and civil work to accommodate new pumps far exceeds the extra cost of a bespoke that can eliminate or minimise disruption.

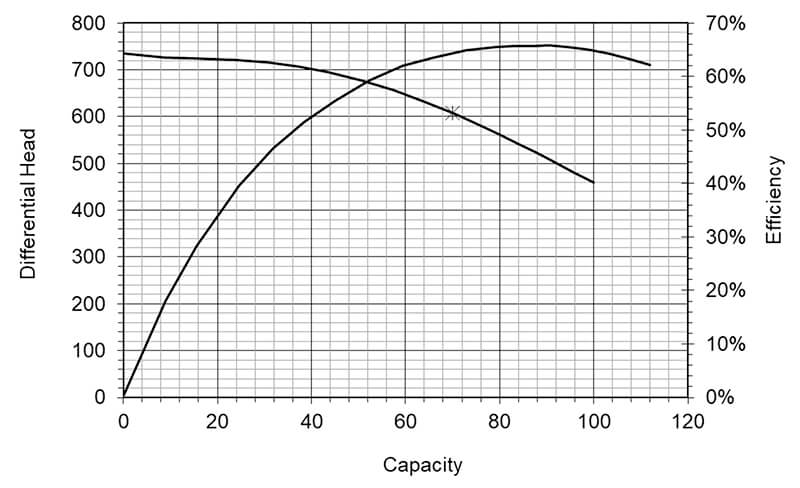

Instructions for Installation, Operation and Maintenance were provided by PumpXP in the form of a IOM manual. Test Results, shown below, were successful and demonstrated low noise levels for this size of pump and vibration levels well within the specified limits of the API 610 standard.